Insulated Glass

Characteristics of the product

Insulated Glass is a type of glass that has spaces between glass which could be one or multiple spaces. These spaces result from using spacers to separate glass, it is therefore possible to look through like normal glass. The main purpose of insulated glass is to reduce heat transfer between indoors and outdoors. The most prevalent spacer used as the middle division is aluminium. An aluminium spacer will be formed with the hole in the middle, and the side that turn towards the space between the glass will have porous part to let the air flow between glass’ space and aluminium spacer’s.

The space of aluminium is a place for putting desiccant. When edges of insulated glass are closed, air will not be able flow in and out between the space inside the glass unit and external atmosphere. Desiccant will absorb humidity out of the air in the glass, letting the air to get dry. Dry air is a good insulator; hence, it enhances a thermal insulation property of insulated glass.

Being a high thermal conductivity material, using aluminium as a spacer will have a weakness for heat release. There are other kinds of spacer which are superior at heat insulation, however these alternatives are unpopular. This is because spacers should not only be adequately strong to handle with force reception and deflection of glass that can occur during the production, but price of spacers also should not exceed that of aluminium. Plastic is one of the examples that can be applied as the alternative.

All kinds of flat glass (float glass, tempered glass, heat-strengthened glass, laminated glass, reflective glass, Low-E glass, and self-cleaning glass) can be a part of insulated glass as long as that particular glass has less than 2 millimeters of deflection.

Having a capability in conducting heat less than dry air, inert glass can be a substitution of dry air in order to intensify thermal insulation properties. Argon is the most common inert gas for producing insulated glass.

The selection of various types of glass and gas will affect properties of glass in terms of thermal insulation, sound resistance, and tolerance towards crash and wind pressure. Superior property may come with higher price. In order to select the best value for money product and ensure the possibility of production and installment, a consultation between an owner, an architect, an engineer, a contractor, and a producer should be held.

Advantages

- Reduce thermal conduction between indoors and outdoors, helping to save energy as air conditioner works more efficiently.

- As two glass separated from each other, heat absorbed by the outer glass will radiate through dry air (thermal insulation). The internal glass will receive scant heat; those sitting nearby will feel comfortable for not getting heat from the radiation of glass.

- Reduce noise from outdoors.

- An allowance to increase durability of glass towards the breakage caused by heat, wind pressure, and smash by selecting suitable glass types for insulated glass.

Disadvantages

- Insulated glass is thick because of the air layer, and accordingly is difficult to lift and lay down due to the heavy weight.

- Based on insulated glass thickness, a supporting groove should be wide. Normal size of aluminium frame cannot be used in this case. The problem is an aluminium frame with an extra-wide glass supporting groove is costly and hard to purchase in Thailand.

- As insulated glass is the result of combining various types of glass together, this particular glass has high price.

Application

Insulated glass is the best at preventing thermal conduction compared to other types of glass. This particular glass is suitable for exterior wall, especially in areas that exposed directly to the sunlight. For indoors where air conditioners are necessary to be turned on the entire time, insulated glass is recommended due to the fact that it will help to reduce the size and quantity of air conditioners, and consequently electricity consumption will be lessened.

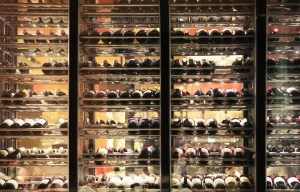

Insulated glass can also be used as a fridge door because it can prevent heat conduction between -18 ºC in the fridge and up to 40-45 ºC outside. Using glass as a fridge door will also allow customers to see inventory supplies before opening the fridge.

Thickness

Thickness: a range from the thinnest at 3+6+3 (12 millimeters) and the thickest at 15+18+15 (48 millimeters).

Smallest

The smallest size: 190 X 350 millimeters.

Largest

The largest size: 2,700 X 5,000 millimeters.

* Remark: The size of thin glass depends on raw materials; hence, please inquire about the size before ordering.

Caution in use

- Insulated glass is made according to the required size. Measuring areas carefully is therefore necessary as a glass unit cannot be cut after manufactured.

- According to the law, insulated glass that will be installed on high rise buildings must be composed with one side made from laminated glass to prevent the broken glass from falling off. More importantly, the side made from laminated glass must be placed as an exterior side.

- In case of using special glass as a component of insulated glass, a consultation with a producer on which part of the glass should be placed outside is essential in order to gain the highest benefits from that particular glass.

Detection whether the glass is insulated glass or not

It is easily detectable as an aluminium spacer used for separating two glass is easy to be seen.